The professional home for the engineering and technology community worldwide.

Electronics Reliability Tutorial Program

Series 3: Reliability in Manufacturing

Series 3 consists of two tutorials.

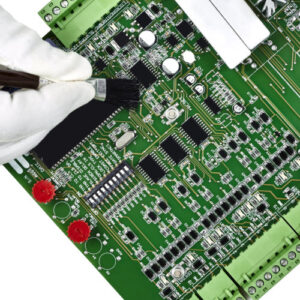

This series focuses on printed circuit board (PCB) assembly, design for manufacturing and impact on reliability.

Incidentals:

- These tutorials are available on demand.

- You will have 180 days to access each tutorial.

- Registration:

- $70.00 for each 2-hour tutorial

- $120.00 for both tutorials in this series.

- Click here to re-direct to the registration page, where you will have the opportunity to select the courses you wish to attend.

Incidentals:

- Price: $70

- Duration: 2 hours

- Instructor: Greg Caswell and David Spitz

Abstract: In the electronics industry, the quality and reliability of any product is highly dependent upon the capability of the manufacturing supplier, regardless of whether it is an internal operation or a CM (contract manufacturer). Manufacturing issues are one of the top reasons that companies fail to meet warranty expectations, which can result in severe financial pain and eventual loss of market share. Engineers and managers need to recognize that both manufacturing processes and design play a critical role in the success or failure of product development.

Designing printed boards today is more difficult than ever before because of the higher lead-free process temperature requirements and associated changes required in manufacturing. The density of the electronic assembly has increased, which has driven the industry to smaller and smaller components increasing the reliability risks.

The course will identify industry standards that help facilitate design for manufacturability (DfM), discuss the root cause analysis process for identifying issues, look at components from the perspective of manufacturing, similarly look at printed circuit boards and how to mitigate issues associated with laminate and pre-preg selection, circuit board cleanliness and ECM (electro-chemical migration), pad cratering and will finally examine the impact of solder on the reliability of the manufactured electronics.

Target audience: Engineers and managers involved in the design, manufacturing and/or reliability of complex printed circuit board assemblies.

Benefits of attending:

- Gain an understanding of different failure modes, associated with manufacturing

- Learn the process for assessing the design and enhance manufacturability with each level of electronic packaging/assembly

- Mitigation methods for the relevant failure modes

- Keywords/Hashtags: Electronic reliability, printed circuit board, failure modes and mechanisms, electronic packaging, reliability physics

Instructor: Greg Caswell

Greg Caswell, a Lead Consulting Engineer for Ansys Corporation, is an industry recognized expert in the fields of SMT, advanced packaging, printed board fabrication, circuit card assembly, and bonding solutions using nanotechnology. He has been well-regarded as a leader in the electronics contract manufacturing and component packaging industries for the past 50 years. He has presented over 270 papers at conferences all over the world and has taught courses at IMAPS, SMTA and IPC events. He helped design the 1st pick and place system used exclusively for SMT in 1978, edited and co-authored the 1st book on SMT in 1984 for ISHM and built the 1st SMT electronics launched into space. Be on the lookout for his new book entitled Design for Excellence in Electronics Manufacturing due out in May 2021. Greg has won several awards including the IMAPS Lifetime Achievement Award in 2018, the ISHM Daniel C. Hughes Award (highest award given to an individual), ISHM Fellow of the Society Award and the Tracor Technical Innovation Award.

Instructor: David Spitz

David Spitz, a Lead Consulting Engineer with Ansys Corporation, has over 30 years of experience in PCBA manufacturing with tier 1 contract manufacturers Texas Instruments, Solectron, and Flex. During that time, he has held various technical leadership roles including SMT and DFM Engineering, and his background has encompassed both NPI and Production environments. David has expertise in BGA/CSP attachment, solder paste printing, and SMT reflow soldering.

Incidentals:

- Price: $70

- Duration: 2 hours

- Instructor: Dock Brown, CRE

Abstract: Contamination issues in printed circuit board assemblies are a key driver in field failures resulting in corrosion and electrochemical migration failures. Decreasing pitch sizes, increasing use of leadless packages, and electronic assembly in polluted or tropical environments are some trends which make contamination related failures more likely. To understand the challenge of contamination and cleanliness, one only needs to look at the many problems associated with high reliability environments, such as those encountered in automotive, and military applications. Particularly, high humidity exposure (85 % RH 85 C) can result in shorting occurring in less than 168 hours, due to dendritic growth and corrosion. Several of these failures are intermittent in nature, and result in no-fault-found (NFF) failures. This issue, in turn, can result from poor cleanliness both before solder mask and after soldering. This course will present:

- Overview of Contamination and Cleanliness

- Drivers: Temperature Effects Humidity/Moisture Effects, Voltage and Electric Field

- Sources of Contamination; PCB fab; Fluxes; Assembly; Handling; Use Environment

- Mitigation Approaches and Conformal Coating

Target audience: Engineers involved in the design, manufacturing, assembly, testing and/or reliability of electronic packages, circuit board assemblies

Benefits of attending

- Drivers for cleanliness in printed circuit board corrosion failures

- Methods for ensuring board cleanliness, test philosophy, mitigation

- Conformal coating mitigation approaches

Instructor: Dock Brown, CRE

Dock Brown brings his more than 30 years of electronics reliability experience to clients of Ansys. Prior to joining Ansys, he spent 20 years at Medtronic where he most recently concentrated on cross business unit implementation of reliability initiatives for Class III medical devices. He was also responsible for supplier assessment and approval, on-going supplier audits, failure analysis, corrective actions, MRB, sampling, and ultimately full accountability for quality and reliability of COTS and custom parts and assemblies from a worldwide supplier base. Earlier in his career, Mr. Brown also spent time at Sundstrand Data Control where he led the implementation of the Boeing AQS program and with Olin Aerospace.

As a volunteer, he has been involved with ASQ, IEEE, IPC, and SMTA. He was the keynote speaker at the SMTA Cleaning Conference. He has taught design for reliability, tin whiskers, statistics, design of experiments, and contributed to standards development. He has won the SMTA Distinguished Speaker award and the SMTA Microelectronics Conference Best Paper Award.

Disclaimers

*These electronic reliability tutorials were originally presented between 2020 -2023. The fundamental concepts in electronics reliability, reliability physics, failure drivers are generally applicable to the industry. However there may be references to the technology node and packaging advancements at the time of the original tutorial, which may not reflect the most recent advancements.

**Greg Caswell and Dock Brown retired from Ansys after significant contributions to the electronics industry.